Memory Nail Tutorial

TOOLS AND MATERIALS

Isopropyl Alcohol (99-99.8%)

Isopropyl Alcohol (70%)

Formlabs Form3L Printer

Formlabs Clear Resin V4

Sandpaper (213Q P800-grit)

ViniMay Metal Chrome Gel Nail Polish

Angelina nail supply Clear UV Top Coat

Nail Filer

X-acto Knife

UV Lamp

CONSTRUCTION STEPS

Preparing the 3D Resin Print

SLA print the file of the nail cover design.

Carefully remove the 3D print from the build plate and soak in isopropyl alcohol (99-99.8%).

Cut the supports from the 3D print.

Once supports are removed, give a rinse in IPA for any remaining support debris.

Using super fine sandpaper (P800), sand all the 3D prints gently to remove any remnants of supports. If needed, you can take an X-acto knife and gently remove any little broken support pieces, but be careful not to cut the model itself.

Coating and Curing the Nail Cover

Apply 1 of the metal chrome nail polish to the nails. Cure with a UV lamp in between each layer.

Once dried, paint the nail cover with a clear UV top coat. Cure with a UV lamp.

FUNCTIONALITY

Circuitry Preparation

Construct the controller circuit following the circuit schematic

It is recommended that the circuit be soldered onto a Perma-Proto Quarter-sized Breadboard PCB for easy use.

Optional: The controller PCB can be assembled inside a 3D-printed enclosure. The enclosure 3D file is attached. The enclosure can be printed either using a SLA printer or a FDM printer. The screws of the enclosure are M2-6 Socket Head Screws.

Testing the Solenoid

Connect the solenoid to the controller circuit.

Program the microcontroller through Arduino. The code can be downloaded below.

Power on the controller circuit either through a USB cable or using a tattoo machine power supply. The supply voltage should be 5V.

The solenoid should be activated in a linear actuation at a fast frequency. Turning the knob of the potentiometer, the speed of the solenoid would change: clockwise → faster speed; counterclockwise → slower speed. The indicator LED will also change color accordingly.

NAIL APPLICATION

Applying the Nail Cover

File the natural nail and the back of the nail cover with a nail filer.

Clean both the natural nail and the back of the nail cover with isopropyl alcohol (70%) and isopropyl alcohol (99-99.8%), respectively.

Apply a clear, double-sided adhesive nail sticker to the natural nail.

Attach the nail cover at a 45º angle from the nail tip to the nail bed.

Removal

Unstick the nail from left to right and remove the remaining sticker tab peeling it off with your fingers.

Gossip Nail

TOOLS AND MATERIALS

Isopropyl Alcohol (99-99.8%)

Isopropyl Alcohol (70%)

Formlabs Form3L Printer

Formlabs Clear Resin V4

Sandpaper (213Q P800-grit)

ViniMay Metal Chrome Gel Nail Polish

D&Z orange and turoquoise gel polish color 313 and 365

Dafu yellow gel polish color M045

Angelina nail supply Clear UV Top Coat

Nail File

X-acto Knife

UV Lamp

CONSTRUCTION STEPS

Preparing the 3D Resin Print

SLA print the two files of the ring and nail cover design.

Carefully remove the 3D print from the build plate and soak in isopropyl alcohol (99-99.8%).

Cut the supports from the 3D print.

Once supports are removed, give a rinse in IPA for any remaining support debris.

Using super fine sandpaper (P800), sand all the 3D prints gently to remove any remnants of supports. If needed, you can take an X-acto knife and gently remove any little broken support pieces, but be careful not to cut the model itself.

Coating and Curing the Ring and Nail cover

Apply one layer of the metal chrome gel nail polish to the nails. Cure with a UV lamp in between each layer.

Apply 3 layers of yellow, orange and turquoise gel nail polish to the nails. Make gradient of colors using a fluffy brush. Cure with a UV lamp in between each layer.

Once dried, paint the nail cover with a clear UV top coat. Cure with a UV lamp.

FUNCTIONALITY

Microphone Circuit

Construct the controller circuit following the circuit schematic.

It is recommended that the circuit be soldered onto a Perma-Proto Quarter-sized Breadboard PCB for easy use.

Program the microcontroller through Arduino. The testing code can be downloaded below.

When talking to the microphone, the on-board LED will dim according to the volume of the sound.

Microphone Visualization

To visualize the sound, program the microcontroller through Arduino. The code can be downloaded below.

To connect the Arduino to the p5.js visualization, p5 serial control need to be installed: https://github.com/p5-serial/p5.serialcontrol

The p5.js visualization sketch: link

Speaker Circuit

Construct the controller circuit following the circuit schematic.

It is recommended that the circuit be soldered onto a Perma-Proto Quarter-sized Breadboard PCB for easy use.

Program the microcontroller through CircuitPython. The testing code can be downloaded below.

To prepare the audio file, prepare the sound file in .wav format using the online recording tool: https://resonaterecordings.com/voice-recorder/

The .wav file needs to be renamed to “audio.wav” and saved to the CircuitPython folder when the microcontroller is connected to the computer.

SKIN APPLICATION

Applying the Ring and Nail Cover

File the natural nail and the back of the nail cover with a nail filer.

Clean both the natural nail and the back of the nail cover with isopropyl alcohol (70%) and isopropyl alcohol (99-99.8%), respectively.

Apply a clear, double-sided adhesive nail sticker to the natural nail.

Attach the nail at a 45º angle from the nail bed to the nail tip.

Removal

Unstick the nail from left to right and remove the remaining sticker tab peeling it off with your fingers.

Laser Nails

TOOLS AND MATERIALS

Isopropyl Alcohol (99-99.8%)

Isopropyl Alcohol (70%)

Formlabs Form3L Printer

Formlabs Clear Resin V4

Sandpaper (213Q P800-grit)

Born Pretty Red Jelly Gel Nail Polish

Angelina nail supply Clear UV Top Coat

Nail Filer

X-acto Knife

CONSTRUCTION

Preparing the 3D Resin Print

SLA print the file of the nail cover design.

Carefully remove the 3D print from the build plate and soak in isopropyl alcohol (99-99.8%).

Cut the supports from the 3D print.

Once supports are removed, give a rinse in IPA for any remaining support debris.

Using super fine sandpaper (P800), sand all the 3D prints gently to remove any remnants of supports. If needed, you can take an X-acto knife and gently remove any little broken support pieces, but be careful not to cut the model itself.

Coating and Curing the Nail Cover

Apply 2 layers of Born Pretty Red Jelly Gel nail polish to the nails. Cure with a UV lamp in between each layer.

Once dried, paint the nail cover with a clear UV top coat. Cure with a UV lamp.

FUNCTIONALITY

Circuitry

Solder five laser diodes to each battery connector. The red wire connects to “SW,” and the blue wire connects to “-”.

Connect 3.7V LiPo batteries to each of the battery connectors.

Before switching on the battery connector, ensure that the laser diode is not pointing at human eyes or camera lenses. Safety goggles are recommended.

NAIL APPLICATION

Applying the Nail Cover

File the natural nail and the back of the nail cover with a nail filer.

Clean both the natural nails and the back of the nails with isopropyl alcohol (70%) and isopropyl alcohol (99-99.8%), respectively.

Apply a clear, double-sided adhesive nail sticker to the natural nail.

Attach the nail cover at a 45º angle from the nail bed to the nail tip.

Nightlife Warrior

TOOLS AND MATERIALS

Isopropyl Alcohol (99-99.8%)

Isopropyl Alcohol (70%)

Formlabs Form3L Printer

Formlabs Clear Resin V4

Sandpaper (213Q P800-grit)

D&Z Black Gel Polish

Angelina nail supply Clear UV Top Coat

X-acto Knife

UV Lamp

CONSTRUCTION

Preparing the 3D Resin Print

SLA print the file of the necklace design.

Carefully remove the 3D print from the build plate and soak in isopropyl alcohol (99-99.8%).

Cut the supports from the 3D print.

Once supports are removed, give a rinse in IPA for any remaining support debris.

Using super fine sandpaper (P800), sand all the 3D prints gently to remove any remnants of supports. If needed, you can take an X-acto knife and gently remove any little broken support pieces, but be careful not to cut the model itself.

Coating the necklace

Apply two layers of the D&Z Black Gel Polish to the words of the necklace. Cure with a UV lamp in between each layer. After applying the final coat, cure with a UV lamp again.

Once dried, apply a clear UV top coat to the words of the necklace. Cure with a UV lamp.

FUNCTIONALITY

Circuitry

Layout SkinLink modules inside each slot on the necklace, and adjust the placement accordingly to avoid bending the flexible connectors

Measure the length between each component, and prepare the SkinLink wiring connectors accordingly.

Program the SkinLink in Arduino. The code can be downloaded below.

2023 Artist Residency Tutorials

AutoLight Tutorial

One day in the future humans might be able to see in the dark without having to turn on a flashlight or wear night-vision goggles. In the meantime, with the aid and versatility of SkinLink, we have AutoLight: A hands-free wearable eyebrow mount that uses an ambient light sensor to turn on automatically in low-light.

Autolight is made up of a SkinLink MCU module, an ambient light sensing module, and a white neopixel LED module as well as elastic resin printed housings for the skin link module, light sensor, and LED.

Aesthetically inspired by the Borg from Star Trek, it boasts a rather conspicuous cyberpunk aesthetic, in hopes to push humans further toward an augmented future with new abilities.

Tools and Materials

Elastic 50A Formlabs resin tank

SkinLink MCU module

Ambient Light Sensing Module

Neopixel RGB LED Module

Construction Steps

Cover and housing design

Create a design with structures that accommodate the SkinLink MCU module, Ambient Light Sensing Module, and Neopixel RGB LED Module

Open the .stl in PreForm and print it on a Formlabs From 3 printer in clear resin

Soak in isopropanol alcohol bath after print

Color the prints with acrylic paint to match the desired skin tone

Circuit Preparation

Layout SkinLink modules on face, adjust the placement accordingly to avoid bending the flexible connectors

Program SkinLink in Arduino

Attachment

Attach the MCU module with DUO eyelash glue

Attach the cover for the MCU with DUO eyelash glue

Attach the housing of sensor and LED modules with DUO eyelash glue

Insert sensor and LED module into their corresponding housings

Power

Insert the battery onto the battery connector on MCU module, tuck the battery behind the ear

ThermalDermal Tutorial

Pain relief envisioned as something you could wear while going out at night. Current heating patches are squares or ovals. ThermalDermal proposes any one-line shape as the substrate for heat. In the example below, it is pictured as a “hot tramp stamp”. A wearable patch that is both physically and conceptually hot.

Tools and Materials

Gennel conductive cloth fabric adhesive tape

Ecoflex silicone 00-30

Thermochromic pigment

Silicone Cover Stranded-Core Wire - 50ft 30AWG White

Vinyl cutter

Xacto blade or box cutter

Construction Steps

Design

Create a 4mm thickness of one-liner 2D design, avoid any intersections

Vinyl cutting the design from tape

Import the design into Silhouette, vinyl cut it on conductive fabric tape

Remove the negative area of the tape

Solder wires

Measure the resistance of the trace, ideal resistance is around 10 ohms.

Solder wires onto each end of the trace

Silicone cast

Mix 5 grams of part A and 5 grams of part B of Ecoflex

Add 0.5 grams of thermochromic pigments

Place the vinyl cut tape on a flat surface, pour the silicone mixture onto the vinyl cut tape to achieve an even layer

After the silicone fully cures, flip it and cut out the shape with a Xacto knife

Attachment

Microporous tape layered across to create desired thickness

Layered uline tape over to desired thickness

Place tattoo on top right side facing out and cut tape layers to fit tattoo

Stick to skin or plastic backing to store

HearingAngel Tutorial

Imagining current wearables less as something to hide and more as something to flaunt and show off. Hearing aids typically tuck discreetly behind the ear for minimal visibility. This project rests in front of the ear, proudly showing off its audacious sculptural and material form.

It mimics a common tattoo motif of an angel whispering in an ear, but doubles as a functional object, amplifying sound. The angel is literally whispering!

Tools and Materials

Formlabs clear resin

Hearing Aid

Construction Steps

Disassembly

disassemble the hearing aid using a screwdriver

Apply hot glue around the wire connection to PCB

Design

Download an ear 3D model

Pose a human mesh around it

Use a boolean to remove the shape of the ear from the model

Use another boolean to accommodate the PCB of the hearing aid

Export .stl file

Open the .stl in PreForm and print it on a Formlabs From 3 printer in clear resin

Soak in isopropyl alcohol bath after print

Assembly

Insert the hearing aid PCB into the 3D print

Apply dots of hot glue onto non-essential areas

CoolingUnit Tutorial

Picturing the surface of the human body as no different from that of a car or personal computer. In the future there might be an increasing need to cool embedded implants. Using 3D printed elastic resin, real PC fans are “installed” onto the surface of skin.

Tools and Materials

Elastic 50A Formlabs elastic resin tank

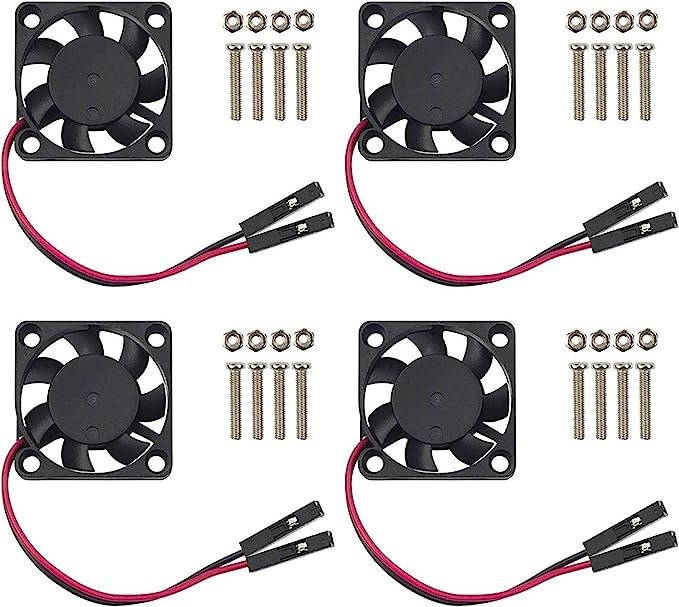

Fan

Battery

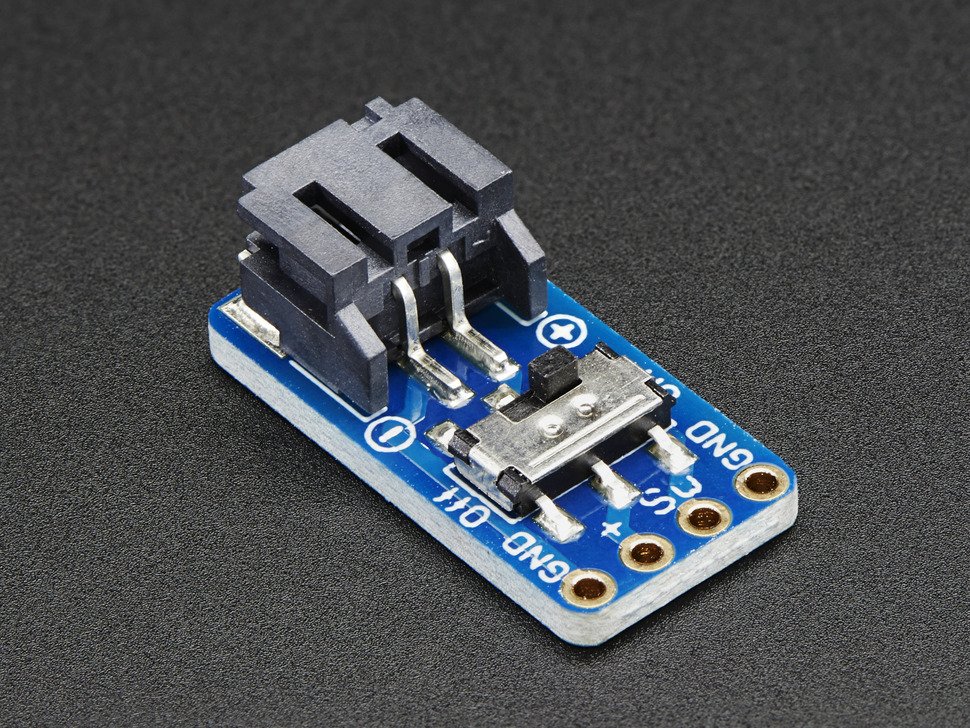

Switch connector

Wires

Silicone Cover Stranded-Core Wire - 50ft 30AWG White

Silicone Cover Stranded-Core Wire - 50ft 30AWG Black

Construction Steps

Resin printing

Open the .stl in PreForm and print it on a Formlabs Form 3 printer in elastic 50A resin

Soak in isopropyl alcohol bath after print

Circuit connection

Desolder wires on the fan, solder silicone-coated stranded wire to the fan, note the polarity: white for + and black for -

Fitting soldered fans into the 3D print

Feed the wires through the channels in the 3D print

Solder the wires to the battery connector, white wires -> SW, black wires -> GND

Apply:

Clean with alcohol swab as needed

Use DUO eyelash glue to apply the CoolingUnit on skin

UVScale Tutorial

UV Scale is a set of flexible resin printed scales that will visually change color under UV light. The scales are to be applied on the skin using a safe skin adhesive in a pattern which emulates a snake's skin as it basks in the sunlight. The pattern of snake skin is an irregular sort of tessellation that easily and naturally warps with the unusual geometry of the human body.

Tools and Materials

Elastic 50A Formlabs resin tank

Photochromic pigment

UV Resin soft type

DUO eyelash glue

Construction Steps

Prepare the resin print

Convert .svg file of scale 2D design to mesh in Blender

Extrude the plane to desired thickness

Export as .stl file

Open the .stl in PreForm and print it on Formlabs From 3 printer in elastic 50A resin

Apply photochromic pigments

Mix 1 gram of purple photochromic pigment into 5 grams of UV resin soft type

Apply the mixture on the edges of each scale piece with a paintbrush

Curing under a UV lamp for 2 minutes

Skin application

Apply DUO eyelash glue onto the bottom of each piece, wait for it to turn tacky and apply them onto skin.

Social Prosthesis Tutorial

Social Prosthesis is a moving appendage designed as two headpieces made from rigid and soft structures. The soft skin of the prosthesis curls and contracts when triggered by touch on the face.

Social Prosthesis is made up of 3D resin print, silicone skin, and an embedded shape memory alloy circuit attached to a Duoskin capacitive touch.

Referencing the definition of prosthetic sociality, written by Mimi Thi Nguyen in the 2003 essay Queer Cyborgs and New Mutants, Social Prosthesis is an exploration of how technologies enhancing the human body create meanings that extend past the merging of biological and artificial—that must contest with the social and political contexts of its time.

Tools and Materials

EcoFlex NearClear 00-45

Shape Memory Alloy Spring, 0.5cm(5mm) coil diameter , 0.15 wire diameter, Pitch: wire size x2, transition temp 45C

Mold for silicone casting

Isopropyl Alcohol 99% - 99.8%

Resin printer

Korea Crystal Tec Transparent Stretchy Beading Line String 0.5 (or any thin, stretchy elastic to hold the nosepiece in place)

Sandpaper (3M Wetordry 213Q P800-grit)

Silicone Pigment (optional—for coloring silicone)

Alcohol Ink (optional—for coloring resin)

Art Resin (optional—for glossing resin)

32 AWG Copper Wires

15k Resistor

SOT23 Breakout Board (as perf board)

Multimeter

Optional: Isopropyl Mysristate

Construction Steps

Preparing the Resin Print

Resin Print

1. SLA print the two files of the Social Prosthesis design.

2. Carefully remove the 3D print from the build plate and soak in isopropyl alcohol (99-99.8%)

3. Cut the supports from the 3D print. The design has delicate and thin details, so it is important to remove the supports to determine that you are not cutting parts of the model.

4. Once supports are removed, give a rinse in IPA for any remaining support debris.

5. Using super fine sandpaper (P800), sand all the 3D prints gently to remove any remnants of supports. If needed, you can take an X-acto knife and gently remove any little broken support pieces, but be careful not to cut the model itself.

OPTIONAL Steps(1-3)

1. If you want to color the resin at this step, you can take alcohol ink and dilute it using isopropyl alcohol to achieve the desired opacity. Then, taking a paintbrush, coat the resin structures with the alcohol ink mixture. The resin will absorb the alcohol ink.

2. If you would like to gloss the resin at this step, take Art Resin and mix equal parts resin (black cap) and hardener (white cap) in a I1:1 ratio in a separate container with a disposable popsicle stick or paintbrush. Be sure to replace the caps correctly on the bottles when complete.

3. Using a (disposable) paintbrush, lightly coat the Art Resin on the resin print surfaces that require gloss. Allow to dry for at least 24 hours.

NOTE: Avoid putting the Art Resin on the surfaces that you want to stick to the face, to avoid creating a slippery surface for makeup application.

Circuit Schematic

FUNCTIONALITY

CIRCUITRY & PREparing SMA

1. Construct circuit following the circuit schematic

2. Crimp the ends of the SMA before silicone casting, in preparation to be soldered to the circuit.

Testing the SMA

1. Using a multimeter, test both ends of the SMA to ensure conductivity.

2. Using a DC power supply, you can test the curling of the silicone to ensure that it is moving as desired.

3. To reset: wait until SMA has cooled, and then manually stretch the SMA back to its maximum length.

Testing Procedure

1. Power the circuit with LiPo battery

2. Turn on switch on the Gemma M0, onboard LED shows yellow

3. Touch temporary tattoo, onboard LED turns purple

4. SMA should start shrinking

5. Wait for 45 seconds

6. SMA shrinking stops, onboard LED turns cyan

Silicone casting with purple color

Fabrication

Casting the Silicone

1. Measure approximately 8g of Part A and approximately 8g of Part B of Ecoflex Near Clear 00-45.

2. Mix the two equal parts thoroughly using a popsicle stick.

OPTIONAL: to color the silicone, drop a pinprick of silicone dye into the clear mixture and mix. If you are trying to make a clear-colored gradient, create a separate silicone mixture with a colored dye.

4. Place into degassing chamber for 10 min to remove any air bubbles

5. Place SMA spring into mold and arrange to be cast into the silicone

6. Pour carefully into the mold, covering the SMA. Make sure the ends of the SMA are uncovered

7. Use a mixing stick or other tool to pop any extra air bubbles

8. Let cure for 4 hours.

9. When cured, carefully remove the silicone from the mold.

Skin Application

Skin Application

1. To apply the headpiece, you can take 3rd Degree and mix a pea-sized amount of Part A and B to create a silicone adhesive for the skin.

2. Once mixed, apply a thick layer to the back of headpiece on the areas that will contact the forehead

3. Press the headpiece with the silicone adhesive to the forehead and hold for 1 minute to let the product cure.

4. Gently test to make sure the headpiece is adhered to the skin. It will not be a super tight hold, but effective enough to hold up the piece securely while also easy to remove after.

5. To apply the nosepiece, hold the nose bridge of the piece to the nose (as if putting on glasses). Use the elastic band to secure in place.

6. The circuit should also be lifted to hide behind the head.

REMOVAL

1. Gently peel the piece off, and remove the silicone adhesive from the back of the headpiece. It should come off in one piece.

2. Use isopropyl Myristate to remove any extra residue